For detailed information, other images and documents, please select individual articles from the following table.

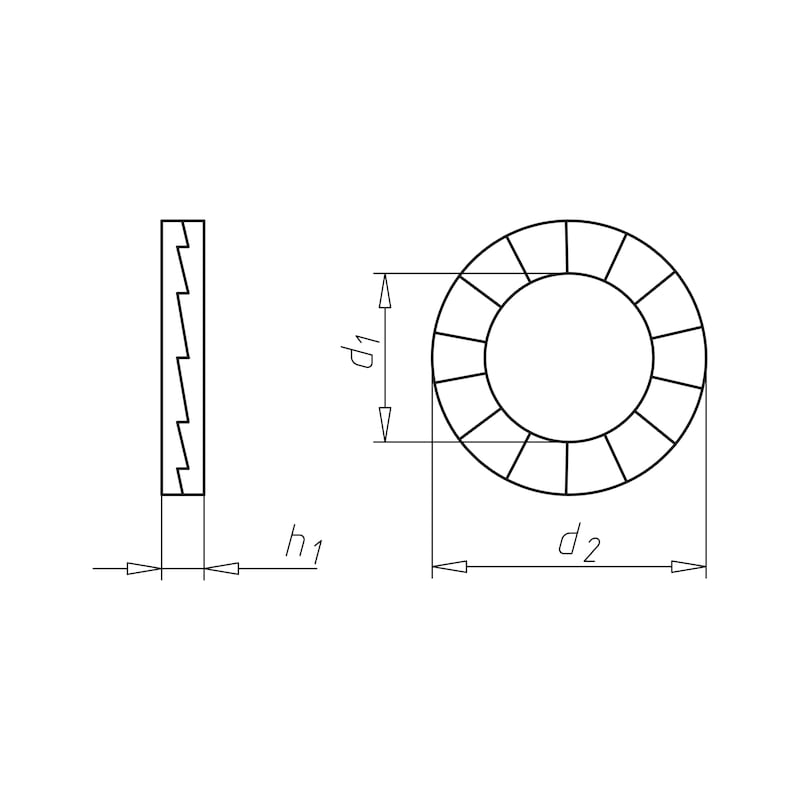

Wedge lock washer W.TEC series, wide shape

Wedge lock washer - effectively secures laterally loaded, vibrating screw connections and screw connections subject to oscillations against self-turning

Register now and access more than 125,000 products

Variants

Register now and access more than 125,000 products

General:

Lock washer in accordance with DIN 25201 to prevent loosening in laterally loaded and vibrating screw connections and screw connections subject to oscillations.

Corrosion resistance:

600 h base metal corrosion in accordance with DIN EN ISO 9227-NSS (DIN 50021-SS) - in comparison: 96 h yellow zinc plated (A2C)

Function:

Highly secure locking as wedge surfaces slope up between the two lock washers. The screw connection is locked by pretension instead of by friction.

Advantages:

- Easy to install and remove (wedge lock washers are already bonded in pairs)

- Tested system for threadlocker (locking elements that prevent unscrewing), at high as well as low tension

- Especially suitable for dynamic loading - including when lubricants are used

- Can be reused multiple times without loss of quality

- Protects surfaces

- Can also be used with high-strength screws 8.8, 10.9 and 12.9 and the corresponding nuts

- Available in stainless steel or steel (other materials available on request)

- With a narrow and a wide contact surface

For screw-nut connections, a pair of wedge lock washers must be used both under the screw head and under the nut. For the recommended tightening torques, please see the technical information in the DIN/ISO catalogue.

Vehicle manufacturing, mechanical engineering, manufacturers of pneumatic and power tools, mining, agricultural machine manufacturing, manufacturers of mixing systems, transport and conveyor systems.

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!