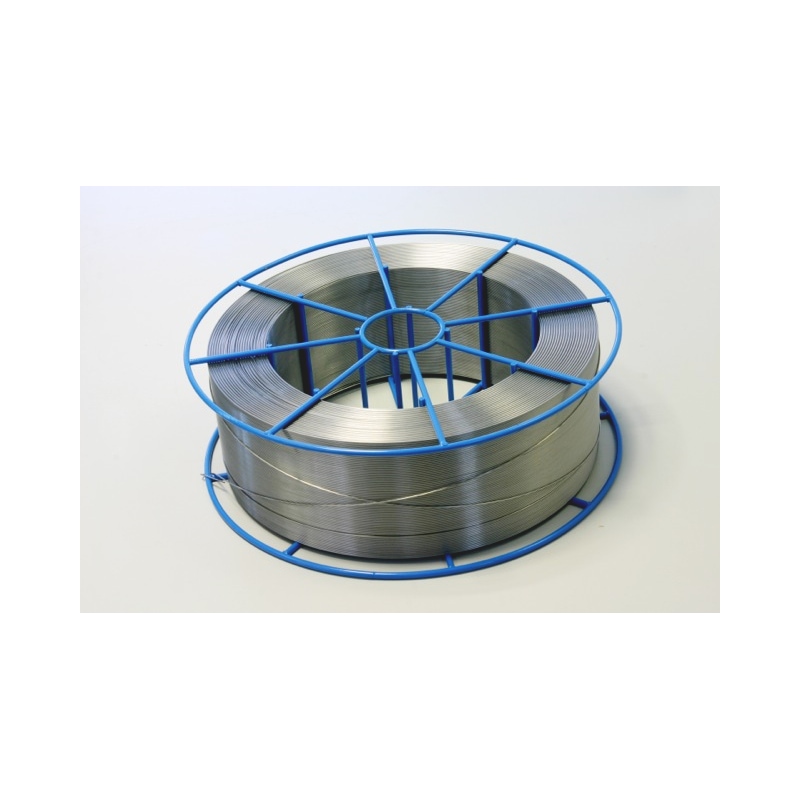

MIG wire 308LSI

MIG welding wire AWS A5.9/ER308LSi

ARGON SHLDD INOX WIRE 308 LSI 1,2MM 15KG

Register now and access more than 125,000 products

Austenitic solid wire made of 19Cr-8Ni alloyed stainless steel with low carbon content.

High silicon content improves bead shape and molten pool behaviour.

Good general corrosion tolerance and nitric acid resistance.

Suitable for welding and coating all 300-series austenitic stainless steels, such as AISI 304 and 304L.

Classification:

AWS A5.9 ER308LSi

EN ISO 14343-A G 19 9 LSi

Material no. 1.4316

Shielding gases (according to EN 439):

M12 Mixed gas Ar+ 0.>5–5% CO2

M13 Mixed gas Ar+ 0.>5–3% O2

Datasheets(X)

Key applications:

Applications requiring good corrosion tolerance in urban and rural environments.

In food and chemical industries, pipes and pipeline construction.

Wire diameter (Ø) | 1.2 mm |

Layer-coiled | Yes |

Weight | 15 kg |

Type of coil | Metal coil B300 |

Material | Stainless steel, 1.4316, X1CrNi19-9 |

Min. longitudinal elongation | 35 % |

Min. tensile strength | 520 N/mm² |

Product weight (per item) | 1.000 g |

American Welding Society (AWS) | A5.9: ER 308LSi |

Shielding gas | Argon/CO2 |