Injectable mortar WIT-PE 500 WIT-PE 500 for concrete and post-installed rebar connection

Injection mortar WIT-PE 500

ANC-MORT-(WIT-PE500)-SBSCART-385ML

Art.-no. 0903480001

EAN 4058794788204

Register now and access more than 125,000 products

Two-component reactive resin mortar, pure epoxy, styrene-free

Individual attachment in cracked and non-cracked concrete, seismic performance category C1 (M12 to M30) and C2 (M12, M16):

Anchor rod W-VD-A, anchor rod W-VI-A, standard threaded rod with acceptance test certificate 3.1

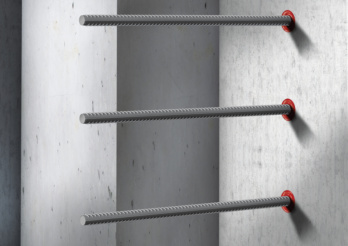

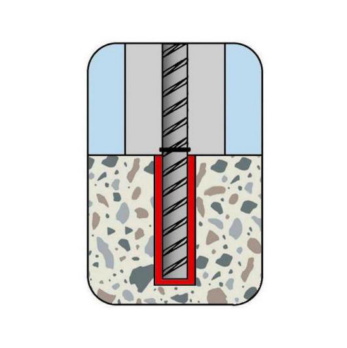

Reinforcement attachment with subsequent mortaring (REBAR)

Cartridge can continue to be used until the best before date, by changing the mixer nozzle or resealing it with the end cap

- European Technical Assessment ETA-09/0040: Individual fixing point + cracked and uncracked concrete (anchor rod W-VD-A, anchor rod W-VI-A, standard threaded rod with acceptance test certificate 3.1), seismic performance category C1 (M12 to M30) and C2 (M12, M16)

- European Technical Assessment ETA-07/0313: Post-installed rebar connection (REBAR)

Post-installed rebar connection (REBAR)

Post-installed rebar connection (REBAR)

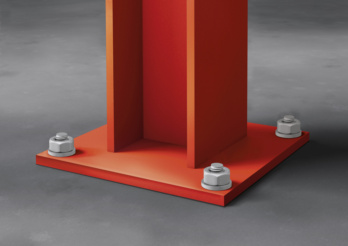

Heavy steel structures

Heavy steel structures

High bays

High bays

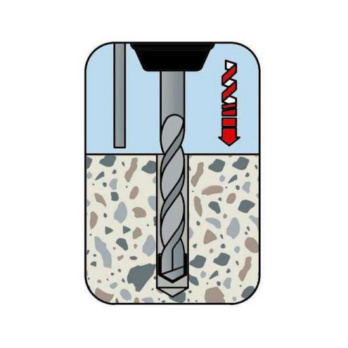

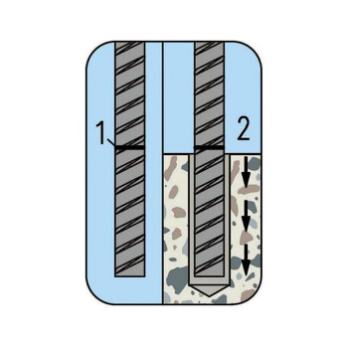

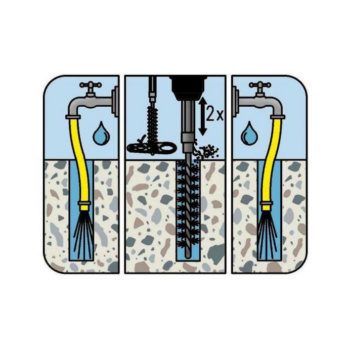

Create the drill hole

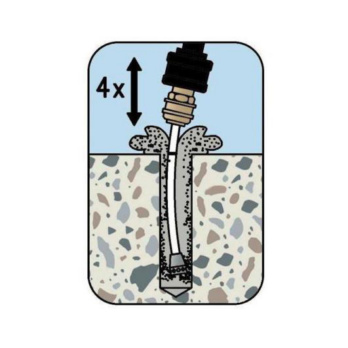

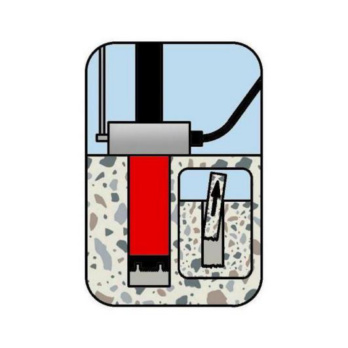

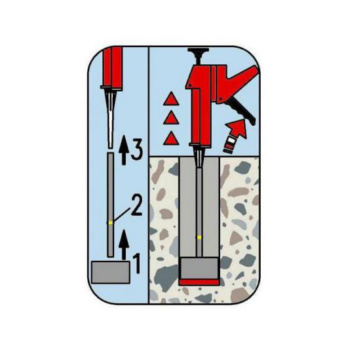

Clean the drill hole: 4x blow out with compressed air > 6 bar

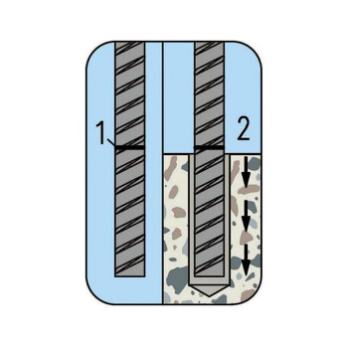

Place the embedment depth mark on the rod and check the drilling hole depth

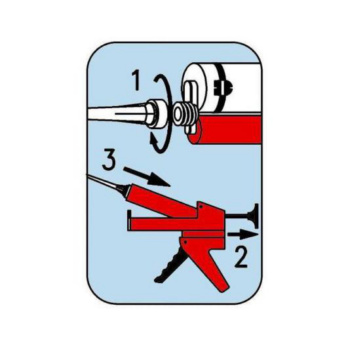

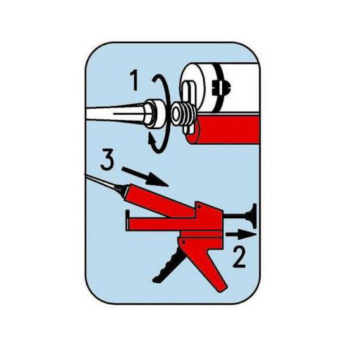

Screw mixer to cartridge; use application gun

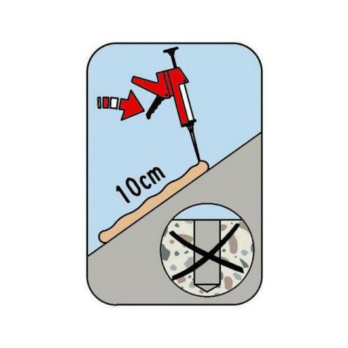

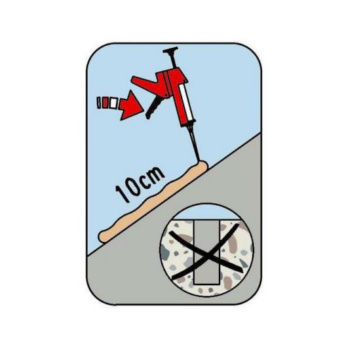

Before using, press out about 10 cm of product (not into the drill hole)

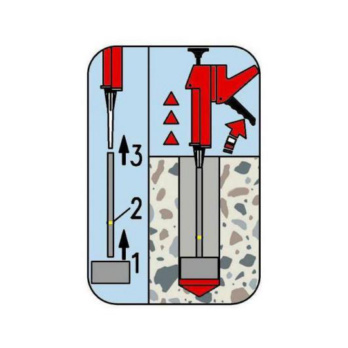

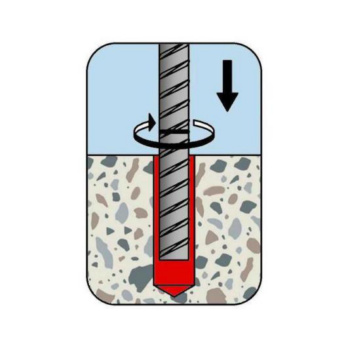

Mount injection equipment, fill composite mortar from bottom of drill hole

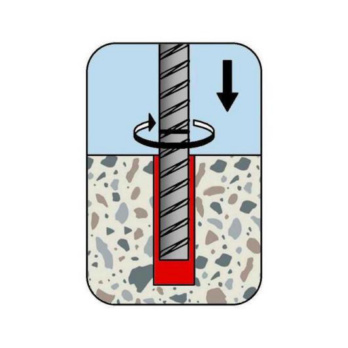

Insert the reinforcement bar until it reaches the mark, turning slightly

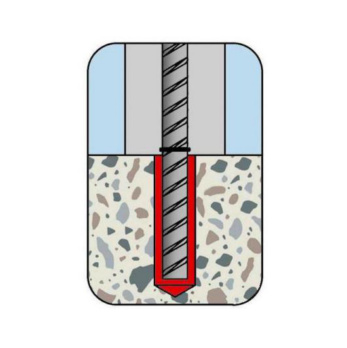

Visual check of the mortar volume, observe maximum processing time

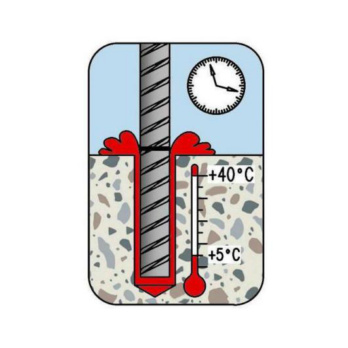

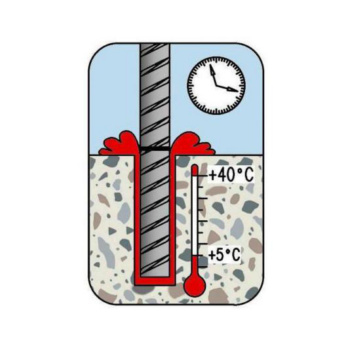

Attach component after observing curing time

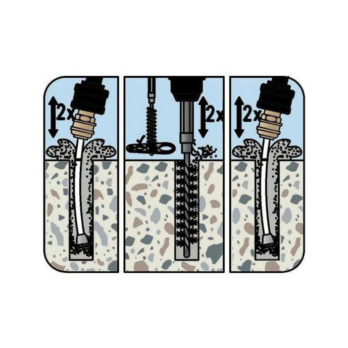

Make the drill hole, break out the drill core

2x flush with water (Until clear water comes)/brush 2x/flush 2x with water (Until clear water comes)

2x blow-out/2x brush-out/2x blow-out

Place the embedment depth mark on the rod and check the drilling hole depth

Screw mixer to cartridge; use application gun

Before using, press out about 10 cm of product (not into the drill hole)

Mount injection equipment, fill composite mortar from bottom of drill hole

Insert the reinforcement bar until it reaches the mark, turning slightly

Visual check of the mortar volume, observe maximum processing time

Attach component after observing curing time

- European Technical Assessment ETA-09/0040: Individual fixing point + cracked and uncracked concrete (anchor rod W-VD-A, anchor rod W-VI-A, standard threaded rod with acceptance test certificate 3.1), seismic performance category C1 (M12 to M30) and C2 (M12, M16)

- European Technical Assessment ETA-07/0313: Post-installed rebar connection (REBAR)

Datasheets(X)

- Suitable for attaching metal structures, metal profiles, wooden structures, brackets, pipes, cable conduits etc.

- Suitable for structural expansions, ceiling and wall attachments, expansion of load-bearing structures, reinforcement of load-bearing structures, attachment of balconies and canopies, sealing of temporary openings and "forgotten" reinforcing bars

Type description | WIT-PE 500 |

Container | Double cartridge |

Contents | 385 ml |

Included in delivery | Mortar cartridge 385 ml (side-by-side) + 1 x mixer nozzle |

Suitable application gun | Battery-powered application gun 585ml, Pneumatic application gun 585ml, EasyMax 385 ml, HandyMax 585 ml |

Min./max. processing temperature /conditions | 5 to 40 °C / temperature in the anchorage ground during processing and hardening |

Min./max. ambient temperature / Conditions | -40 to 72 °C / after completely curing process |

Temperature resistance, long-term temperatures max. | 43 °C |

Temperature resistance, short-term temperatures max. | 72 °C |

Shelf life from production/conditions | 24 Month / cool and dry storage area, 5°C to 25°C |

Approval | ETA-09/0040, ETA-07/0313 |

Chemical basis | Pure-Epoxy, styrene free |

Colour | Red |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!