ASSY® 3.0 HB timber screw

ASSY 3.0 HB steel zinc plated yellow PT AW

SCR-CS-CTRHD-WO-AW30-(A2L)-5X100/52

Art.-no. 0170650100

EAN 4047376854918

Register now and access more than 125,000 products

Tip

The 25° tip enables precision positioning. Screw with mating thread in tip area, which greatly reduces the splitting forces of the wood, especially in the edge area. The screw-in torque is considerably less than with conventional particle board screws and extends the service life of the processing machine and the bit insert.

Thread

The plastic glide-coated asymmetrical coarse thread means a 30% saving in working time.

Shank milling cutter

The milling section after the thread reduces the screw-in torque by 20%.

Thin shaft

The thin shaft enables a tension-free connection without gaps.

Countersunk milling head

60° countersunk milling head for easy, clean countersinking in solid construction wood and coated wood panel materials.

AW® drive

- Enhanced force transmission

- Optimal centring

- Long service life

- Uniform force distribution prevents damage to surface coating

Do not use the screw in applications with direct exposure to the elements, in humid rooms and in atmospheres containing chlorine gas.

The screws are not suitable for outdoor use and for rooms subject to short-term or continuously high moisture levels! Please use ASSY® 3.0 A2 stainless-steel screws in these cases. The surface coatings of nickel and brass are suitable for decorative purposes only = no corrosion protection!

ASSY 3.0 chipboard screws are optimised for use in wooden materials. Use in plastic anchors may cause a reduction in the load-bearing capacity. Therefore, we recommend only using screws without optimised thread tips (drill tip, mating thread, ring thread, serrated edge, self-clearing groove, etc.) in plastic anchors, e.g. Würth ASSY D, prefix number 0151 (countersunk head) and prefix 0153 (pan head)

When using these screws, the ETA-11/0190 specifications must be observed.

Available work documents:

Timber dimensioning software, load tables and detailed processing instructions can be found on the service page www.wuerth.de/assy.

ETA–11/0190

Datasheets(X)

CAD data (available after login)

For wood-wood screw connections where poorer-grade wood qualities are used.

Screw-in angle 0° to 90°. For coniferous wood or wood-based materials made from softwood, the screw connection is made without pre-drilling. To reduce the edge distances, a pre-drilled hole can be made according to the core diameter. When screwing into hardwood, pre-drill according to ETA-11/0190.

| |

Colour | Yellow |

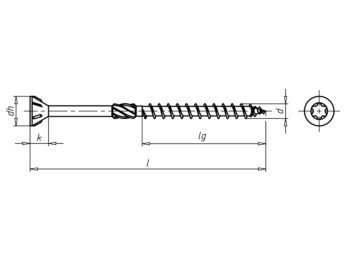

Nominal diameter (d) | 5 mm |

Length (l) | 100 mm |

Thread length (lg) | 52 mm |

Head type | Countersunk milling head |

Head diameter (dh) | 10 mm |

Head height (k) | 4.7 mm |

Head details | Milling edges |

Internal drive | AW30 |

Thread type | Wood screw thread |

Thread form | Coarse thread |

Thread design | Partial thread |

End milling cutter | Yes |

Design | With shaft |

Core diameter | 3.2 mm |

Shape of tip | Tip with counter thread |

Angle of the tip | 28 Degree |

Material | Hardened steel |

Surface | Zinc plated yellow |

Max. screw-in angle | 90 Degree |

Min. screw-in angle | 0 Degree |

Suitable for use in the following materials | Board ply wood (BSP), Wood, Wood with a high amount of branch, Derived timber product, Hardwood, LVL, Softwood |

Area of application | Element construction, Wood, Timber construction, Formwork |

Approval | ETA-11/0190 |